|

|

|

|

|

|

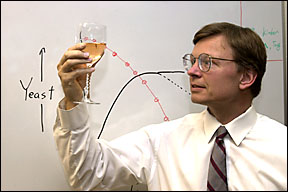

INSIDE IOWA STATE February 23, 2001 Standard methods produce new resultsby Skip DerraHigh-tech chemical techniques can separate materials at the molecular level. But if scientists want to separate and analyze microorganisms -- like bacteria, viruses and fungi -- they still operate with the methods of yesteryear: isolate a culture and grow it. "Louis Pasteur and Robert Coch from the 1800s would recognize some of what is being done in a micro-biology laboratory today," Dan Armstrong said. Armstrong, Iowa State's Caldwell chair of chemistry, and his research group, all of whom arrived on campus last August from the University of Missouri at Rolla, have developed new methods for (living) microbe separation and analysis that are quick, accurate and comparatively easy to perform. The best part about the new techniques is that they use the standard methods of molecular separation with some modifications for microbes. Armstrong already is one of the most highly cited chemists in chemical separations. His microbe separation methods could open new avenues for separating and quantifying microbes, which in turn could aid the detection of diseases, discern the amounts of bacteria (harmful and beneficial) in commercial products, and even monitor the fermentation processes of wine and beer. The work has caught the eye of companies looking either to test their products or provide a testing service. Armstrong has several patents pending on the new methods. "Our work is a cross between chemistry and biology," Armstrong said. "We are the first to succeed in ultra-high efficiency separations and quantification of several micro-organisms in one run." In many cases, Armstrong and his researchers have succeeded in separating down to a single microbe. To date, the researchers have used standard techniques to diagnose urinary tract infections, as well as identify living and dead microbes in a sample. The latter has the potential to analyze sperm samples in helping assess male fertility. "In a few minutes, we can identify a bacteria, even among other bacteria, determine how much is there, and determine the viability -- the percent live, percent dead," Armstrong said. "All in one run." In a recent demonstration, Armstrong and his colleagues analyzed dietary supplements using the established molecular separation method called capillary electrophoresis (molecules are separated by placing a sample under an electric field). This, however, was the first time the process was used to separate microbes. The process allowed Armstrong's team to analyze the supplements for bacteria. They found Lactobacillus acidophilus, which is used in health products for lactose intolerant people, and Bifidobacterium infantis, which is used to inoculate newborn babies with the proper stomach bacteria. An important commercial use for such a microbial separation technique could be as an assay -- the method to accurately determine a product's components, including living components such as bacteria. "It would be impossible to put a drug or a chemical on the market that didn't have an assay," Armstrong said. "It is required by the FDA. So here you have something with an active ingredient, a microbe, but there is no assay for it. This could be that assay. Microbes are fighters While the team is using known techniques, applying them to living microorganisms is no easy feat, Armstrong said. Half the battle is in getting the microbes to behave themselves. "Microbes don't want to behave like molecules. They do all sorts of things molecules don't do," Armstrong said. "If you have two or more in one solution, they tend to fight with each other. They stick to each other. They release things into the solution to attack other microbes, they lyse them, to break them apart. So you have to figure out ways to stop or suppress this long enough to do the analysis." Armstrong believes his team is only dipping its toes into what's possible with these new microbe separation techniques. For example, the team currently is using the technique to monitor fermentation processes, which are widely used in the food processing, drug and biotechnology industries. The team is working with an Ames wine maker to monitor his fermentation processes. Fermentation is integral to making wine and beer by converting sugar into alcohol and other by-products. "The way they generally monitor fermentation is by monitoring the starting product and what is produced, not by monitoring the organism itself," Armstrong said. "Now you can get a direct measure of the organism. We hope to monitor it and do actual growth kinetics of the microorganism. By determining the percents live and dead, we can determine the rate at which the microbes are dying as well as growing. "This will be fun and interesting," he added. "We are just learning all we can do with these techniques."

|

|

Ames, Iowa 50011, (515) 294-4111 Published by: University Relations, online@iastate.edu Copyright © 1995-2001, Iowa State University. All rights reserved. |